Proposal for kf effective notch factor estimation for life assessment of welded joint based on geometric parameters

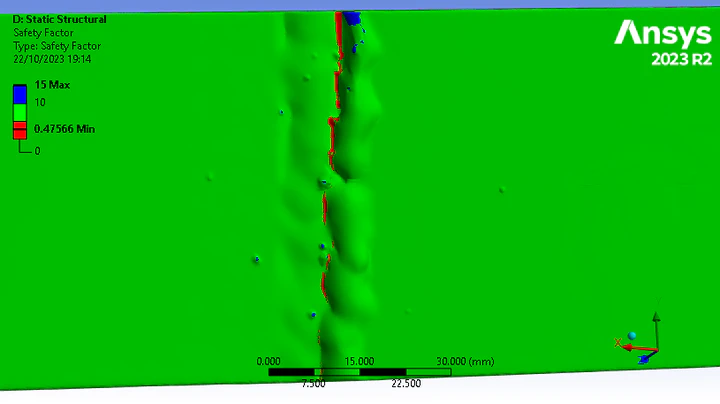

Fatigue Safety Factor on a 3d scan of a welded joint

Fatigue Safety Factor on a 3d scan of a welded jointAbstract

Mechanical joiningtechniquesarefundamental intheindustrial landscape,withweldedjoints standingoutasaprimarymethodacrossdiversemanufacturingsectors.Inthiswork,wepresent anovel contribution to fatigue lifeassessment ofwelds through3D-Scanningofweldseam. Themethodologyisappliedonweldedspecimenstestedinalternatebendingfatigue, showing that forrealcaseapplications, statisticalapproachtosurfaceirregularitiesof thejointplaysa keyrole. Inparticularbymeansof surfacescanning, somestatisticalgeometricparametersare obtainedtocharacterizetheweldseam.Thenbyexperimentalfatiguetestingarelationbetween geometricalmeasuredparameters, experimental cycles tofailureandcracknucleationsites is obtained. ThenFEMmodels generatedbasingon3dscanningareused forFEMsimulations aimingat validating the stress concentration related to surfacegeometric irregularities and fatigue life.Adedicatedsoftware, called3D-life,wasdevelopedtoprocess surfacescansand the results of thenumerical simulationand life estimationswereused topredict the crack nucleationsites.

Type

Publication

ENGINEERING FAILURE ANALYSIS