Frequency-based analysis of active laser thermography for spot weld quality assessment

Neural Network Architecture

Neural Network ArchitectureAbstract

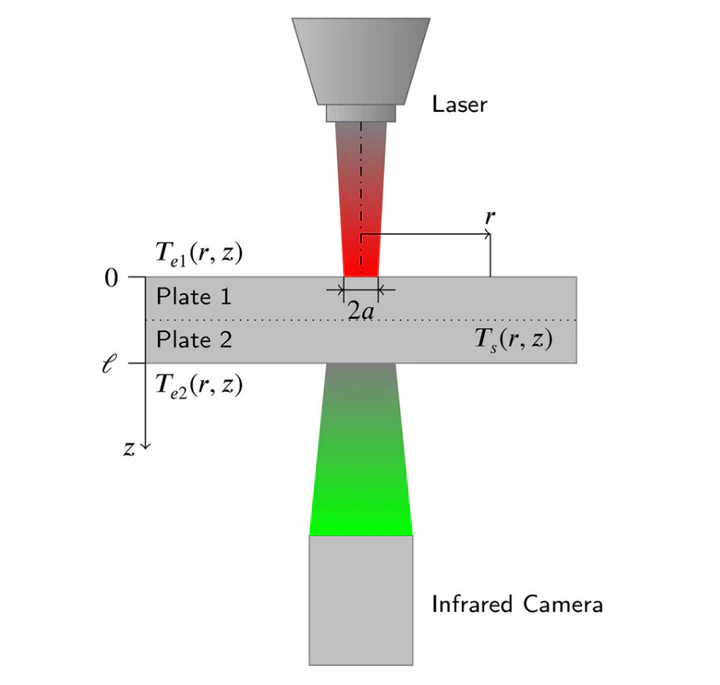

Resistance spot welding (RSW) is a widely employed technique for joining metallic components in different sectors of various industries. However, the quality of the weld joints has a significant influence on the mechanical properties of the joints. This paper presents an innovative non-destructive inspection technology based on active thermography for assessing the welding quality as a function of the peak load. By employing a frequency-modulated laser heat source, we analyze the thermal signal that traverses the weld joint section. Then, we establish a correlation between welding quality and the information derived from spot size and internal uniformity analysis. Furthermore, the proposed methodology shows potential for in-line testing of resistance spot welding, offering easy automation and enabling the classification of spot-welded joints

Type

Publication

INTERNATIONAL JOURNAL, ADVANCED MANUFACTURING TECHNOLOGY