About Me

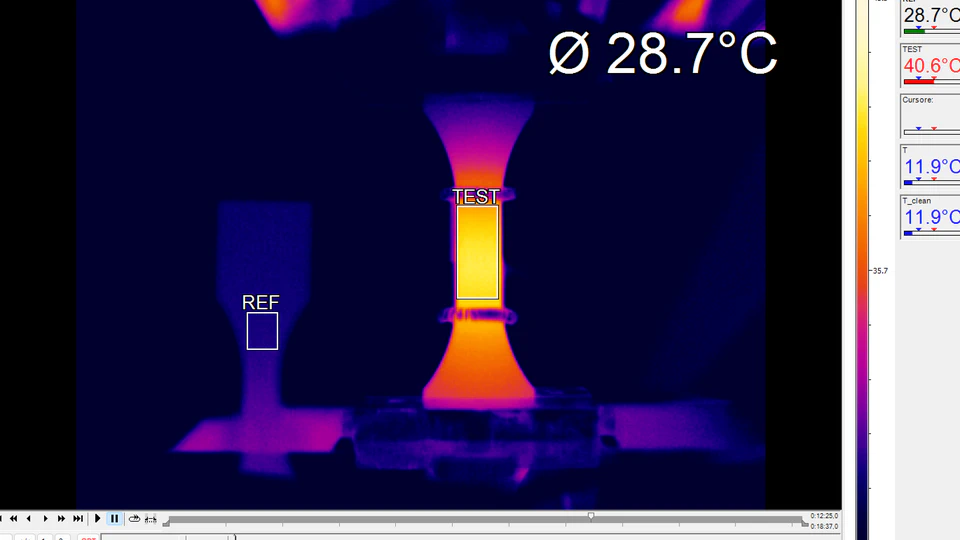

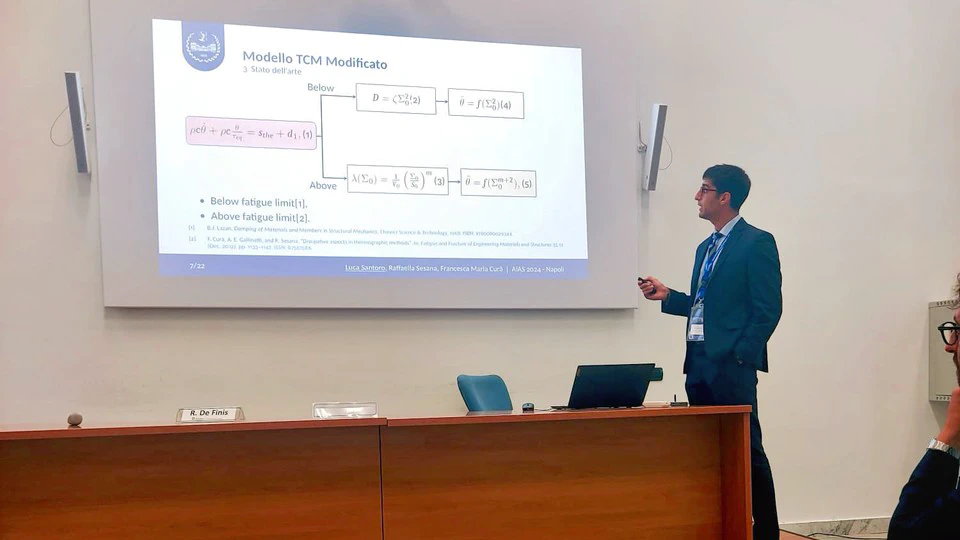

I am a dedicated researcher at the Politecnico di Torino, within the Department of Mechanical and Aerospace Engineering. My expertise lies in non-destructive testing techniques and the mechanical fatigue of materials. I specialize in active thermography and innovative ultrasonic applications, with a recent focus on using thermography for monitoring welding processes. My work has led to significant industrial applications and the development of patents, contributing to advancements in the field.

🚀 Commercial Impact

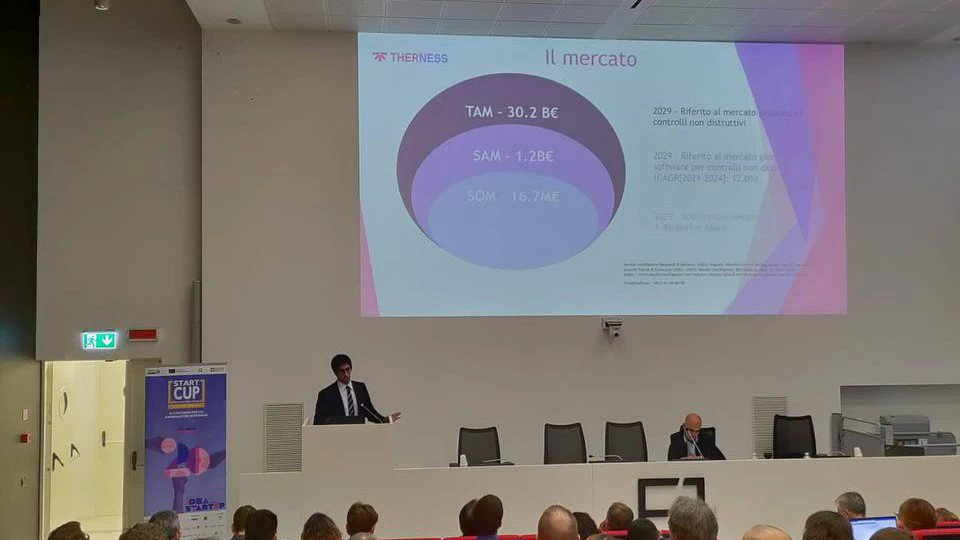

My research has successfully translated into Therness, a cutting-edge spinoff company that revolutionizes welding quality control through AI-powered inspection systems. Therness offers:

- QMS Copilot™ - ISO 9001-aligned, AI-powered Quality Management System that centralizes documents, automates CAPA/PPAP, and delivers real-time SPC insights

- Complete Product Portfolio - From entry-level thermal systems to advanced multi-modal platforms including HeatCore™, VisiCore™, and SugarCube Cam™

The company has achieved remarkable results: €1.2M annual savings for European manufacturing clients and 85% reduction in scrap through early defect detection.

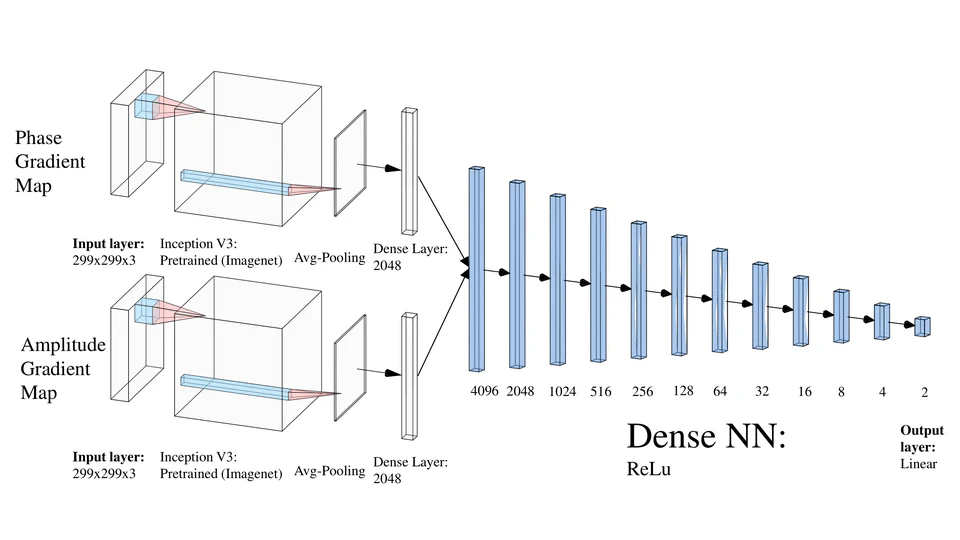

- Artificial Intelligence

- Non Destructive Testing

- Weldings

PhD Machine Design

Politecnico di Torino

MEng Mechanical Engineering

Politecnico di Torino

BSc Mechanical Engineering

Politecnico di Torino

I’m a research scientist specializing in Non Destructive Testing and Machine Design. I currently work as a Scientist at the Politechnic University of Turin. I frequently explore topics like fracture mechanics, computer vision, and the application of advanced testing methods in engineering.

I employ both qualitative and quantitative approaches to deeply analyze the intersection of science, engineering, and technology in industry applications.

🚀 Spinoff Success: My research has led to the creation of , a cutting-edge company specializing in AI-powered welding inspection systems that ensure 100% weld verification with zero guesswork.

Feel free to connect for collaboration opportunities 😃

My research in active thermography and non-destructive testing has led to the successful creation of Therness, a cutting-edge spinoff company that revolutionizes welding quality control through AI-powered inspection systems.

Key Achievements:

- €1.2M annual savings achieved by European manufacturing clients

- 85% reduction in scrap through early defect detection

- 100% weld verification with zero guesswork

- Tech4Planet investment for scaling operations

Therness represents the successful translation of academic research into industrial innovation, demonstrating the power of university-industry collaboration in advancing manufacturing technologies.

| |